Climate change and pollution are two of the biggest challenges the world faces today. A huge contributor to this problem is textile waste. With no efficient and inexpensive methods to sort and recycle textiles, most clothing eventually ends up in our landfills. In 2014, approximately 16 million tons of textile waste was generated in the United States alone. With Identifybre, our team will aim to tackle the sorting portion of this problem by coming up with an inexpensive device that can accurately and efficiently sort different types of textiles.

An Environmental Issue

In 2014, approximately 16 million tons of textile waste was generated in the US alone. The recycling of two million tons of clothing per year equates to taking one million cars from U.S. streets.

Currently, there is no efficient and cost-effective way to properly sort and recycle textiles.

Textile Waste Recycling Flow

The journey to sustainable clothing.

Discarded textiles are collected

Textiles are sorted and separated

Textiles are broken down and new fabrics are created

Recycled fabrics made into clothing & other products

About Us

We are a group of 5 Mechatronics Engineering students completing a final year capstone project at the University of Waterloo.

Come see us at Symposium!

March 13, 2020 | University of Waterloo, Engineering 7

Recent Posts

Blog Posts

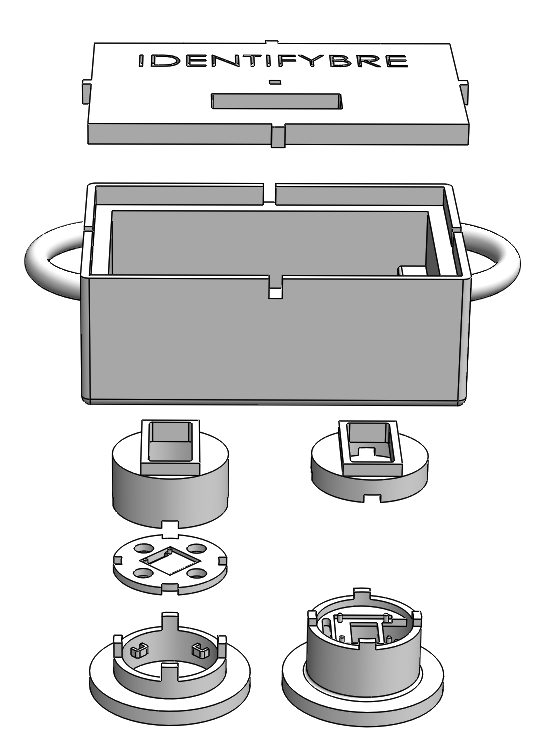

Final Mechanical Design

With the sensor specific encasing complete, all that was left was to put those two sub-assemblies together and have an enclosure to hold the raspberry PI, breadboard and all the electrical wires. A few aspects of this design: Airflow was required to keep the electrical components at a stable level so slots were added to…

Overview Series: The Next Steps

Welcome to the sixth and final instalment of the overview series! We will be discussing the next steps. The textile classification sensor as it is right now is great for many reasons as discussed in the fifth instalment. In order to improve the following steps will be taken. Work will be done to: Sort between…

Overview Series: The Benefits

Welcome back to the overview series! In the fifth instalment the results from the benefits of the current design of the sensor are discussed. During the brainstorming and prototyping of this project, multiple designs were considered. In the end a classification sensor was decided on as the one the team will pursue. The following are…

Overview Series: The Prototype Results

Welcome back to the overview series! In the fourth instalment the final results from the computer vision model is discussed. Our final iteration of the computer vision model is a ResNet50 multi-class classification model that classifies between cotton, denim, and polyester. During training, regularization and data augmentations (blur, affine, etc) were used to artificially increase…

Prototype 2: A clearer vision

After the initial testing prototype. The team was ready to put the camera sensing and IR sensing together. Using the 3D printed parts from the last design, the team put the parts together to make a make-shift demo prototype. This prototype was functional and able to detect clothing. This prototype will be used to demo…

Overview Series: The Solution

Welcome back to the overview series! Here is the third instalment that goes through the solution developed. The textile classification sensor can be broken down into three main components: Mechanical, electrical, and software. The mechanical design of the sensor is a portable, custom-fit, aesthetically pleasing design that was 3D-printed. After initial designs, a few iterations…

Overview Series: The Problem

Welcome back to the overview series! Here is the second instalment that goes through the main problems we found. Fast fashion has propelled a culture of continuous buying and throwing away of clothing. Rather than the traditional 2 cycles per year, fast fashion puts out an average 50 cycles per year of new clothing lines,…

Overview Series: The Objective

This is the first post in the overview series which will be a series that summarizes the journey the group went to in order to create the final textile classification sensor! The journey to choosing this project started off with the desire to create something that would help to make the world a better place.…

Replacing Wool with Denim in CV

Attempts were made to improve the accuracy of the detection of wool using computer vision but the average recall remained around ~40% on the validation dataset. We suspect this is largely due to the lack of original samples for wool (only 90 in our dataset) in addition to the similarity of the texture of wool…

Mechanical Design: 3D printed encasings

Now that an initial prototype was complete, the team decided that 3D printing would be the best way to custom-make encasings for each of the sensors. The IR sensor would have it’s own encasing specific to it’s features. The camera similarly would have it’s own encasing. The camera encasing was left at 2 pieces. One…

Prototype 1: The first step

After a great initial design, and planning, the team realised that an initial test set-up was needed. Although we had a final design in mind, a prototype testing apparatus would allow us to set-up the sensors and get the electrical and software components fully functional before the final installation. The testing set-up would just need…

Mechanical Design update

In terms of mechanical design, the project took some what of a pivot. Since the sensors and the detection part was not complete, this limited the scope and mechanism of the mechanical component of the project. Rather than having a automated removal of the clothing, instead two different concepts where looked at. A easy to…

Computer Vision

Attempt 1 We were able to find a dataset composed of close up images of different types of fabrics. We decided to train a deep learning network to classify the type of fabric given such an input. As a starting point, we decided we want to classify between 3 different types – cotton, polyester, and…

NIR/VIS Sensor Data Testing

Today, we hooked up the spectral sensor to Arduino Uno through i2c connection and recorded the outputted spectral colour values for 3 different types of textiles (cotton, polyester, wool), while controlling the distance of the textile from the sensor, the lighting (natural), and recorded 3 trials for each. The colour of the material has an…

New year, new us

Stay committed to your decisions, but stay flexible to your approach. — Tony Robbins. We came together and made a game plan for the project. The photodiode we had ordered last term is not giving a response – we suspect it is broken. A quick look at Digikey gave way to an unfortunate realization…the sensor…